| [Home] [Product Search] [Contact] [Terms of Trade] [News] [Newsletter] [Product Sitemap] |

[Cart]

|

Article Groups

Service

| Your position : Plating Equipment : High Current Contacts for Rack Systems : Contact Saddles - Two Piece Model 4000 - 14000 A |

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

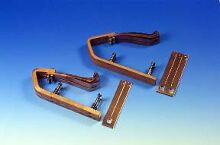

The 4000 A and up range, proven for many years. The standard version is supplied as a contact pair, i.e. delivered in two non connected halves. This allows the contacts to be set individually according to the bus-bar thickness for installation. The installation distance of the contact halves must be less than the thickness of the bus-bar (depending on the contact block or weight of the bus-bar 4 – 6 mm; consultation required). Inserting the bus-bar works with the bar’s own weight which makes these contacts very efficient for fully automatic operation. Additionally, the bars slide cleans the surface of the contact areas. All contact block sizes can also be delivered as a complete ready-to-install unit with base consisting of a mounting plate and connection bar (flat or angled) as well as the insulation plate. To increase the mechanical stability and to protect the unit against acid and alkaline spillage, we recommend our stainless steel protective covers. The contact units are very maintenance friendly being built according to a modular principle. Complete contact elements (contact fingers including installed foils and fixing accessories) as well as individual replacement foils are available as standard replacement parts.

|

High Current Contact Saddles

4000-14000 A

Two Piece Model

|

Part No.

|

Part

No. |

Part

No.

|

max. |

Suitable bus-bar height |

Number of contact fingers |

Dimensions mm |

Weight kg/piece without base |

||||||

|

L |

L1 |

B |

B1 |

H |

H1 |

S |

|||||||

|

4000 A |

160 - 250 |

14 |

95 |

35 |

185 |

130 |

240 |

180 |

20 |

21,70 |

|||

|

6000 A |

160 - 250 |

16 |

95 |

35 |

200 |

145 |

240 |

180 |

20 |

25,80 |

|||

|

7000 A |

160 - 250 |

20 |

95 |

35 |

230 |

175 |

240 |

180 |

20 |

30,20 |

|||

|

8000 A |

160 - 250 |

24 |

95 |

35 |

270 |

215 |

240 |

180 |

20 |

34,00 |

|||

|

10000 A |

160 - 250 |

32 |

95 |

35 |

330 |

275 |

240 |

180 |

20 |

43,20 |

|||

|

12000 A |

160 - 250 |

40 |

95 |

35 |

390 |

340 |

240 |

180 |

20 |

51,10 |

|||

|

14000 A |

160 - 250 |

48 |

95 |

35 |

440 |

410 |

240 |

180 |

20 |

59,70 |

|||

|

30702 1 Piece installed mounting guide |

Part No. 30691 Replacement spring – Stainless steel, Heavy version |

||||||||||||

|

17198 Replacement foils, Type – 2 fold |

Part No. 30692 Replacement spring – Stainless steel, Heavy duty version |

||||||||||||

|

17199 Replacement foils, Type – 3 fold |

|||||||||||||

|

Note: All contacts are built modularly with E-Cu foils screwed into place so that individual foils or the complete contact element (contact finger with foils and fixing materials) can be replaced. When ordering contact blocks with a base, please indicate the bus-bar height and thickness. |

|||||||||||||

Protective Covers – A4 Stainless Steel

Suitable for Contact Saddles 4000-14000 A

Normal Version |

Heavy Duty Version |

|

Part No.

|

Part No.

|

Suitable for contact block |

Dimensions mm |

||||

|

Load |

Part No. |

L |

B | H | H1 | ||

|

4000 A |

20011 |

95 |

135 | 255 | 205 | ||

|

6000 A |

20022 |

95 |

150 | 255 | 205 | ||

|

7000 A |

20033 |

95 |

180 | 255 | 205 | ||

|

8000 A |

20044 |

95 |

220 | 255 | 205 | ||

|

10000 A |

20055 |

95 |

280 | 255 | 205 | ||

|

12000 A |

20066 |

95 |

345 | 255 | 205 | ||

|

14000 A |

20077 |

95 |

395 | 255 | 205 | ||

|

Note: Heavy duty protective covers have an additional 10 mm stainless steel guide integrated and are especially suitable for use with heavy bars. The heavy duty version is approximately 20 mm higher than the figures shown in the table and approximately 8 mm wider. |

|||||||

|

up

-

Print page

-

info@druseidt.de

Copyright © 2000-2019 P. Druseidt Elektrotechnische Spezialfabrik GmbH & Co. KG Neuenkamper Strasse 105 - 42855 Remscheid - Germany Tel.: +49 (2191) 9352-0 - Fax: +49 (2191) 9352-150 |